INTRODUCTION

The disposal of tires represents a significant burden on the environment, so we at ECOPAINT Corporation have developed methods to recycle and reuse old tires.

Due to the large volume of tires produced, these are a challenging source of waste, mostly because of their durability and the components in the tire that are ecologically problematic.

Landfills currently have valuable space consumed because tires are highly durable and non-biodegradable.

In certain countries, you pay a recycling fee when you buy a new tire. Funds collected from the tire fee support Scrap Tire Program that is dedicated to ensuring the cleanup of illegal scrap tire stockpiles and to managing the collection, transportation and processing of the scrap tires.

Importance

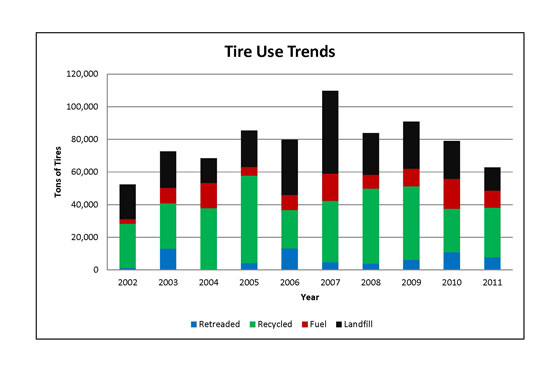

Thanks to newer technology, such as pyrolysis and devulcanization, tires are now suitable targets for recycling despite their bulk and resilience. Aside from being used as fuel, the main end-use for tires remains ground rubber.

Advantages

- Noise and Environment – Low Impact

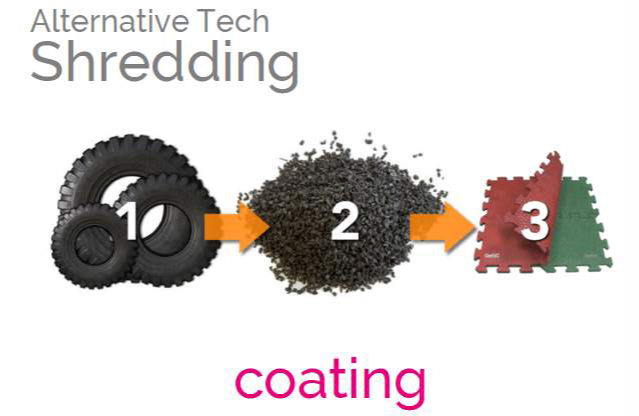

- Shredding as an alternative tech

- Shredded rubber sizes

- Carpet

- Furniture

- Footwear

- Coating

- Rubber Mats

The following is a sample of possible customers for tire-derived fuel products:

- Electric utilities

- Pulp and paper mills

- Cement plants

- Institutional and industrial boilers

- Dedicated tire-to-energy plants

Project Details

- 8 Years Project Duration

- 2 Years Simple Amortization

- 180% Simple Profitability at 22%/Year

- 150 days – Quick Deployment

- 20 ton/day Daily Production

- Thermal Pyrolysis without combustion as Main Tech

- Output – End Products

oil 33%

carbon 45%

steel 22% - Energy

1.0 MWh e

1.5 MWh th - Plant and Equipment Certification by European Standards (EEC)

- 24/7 on-line monitored production & operation

- 6 Workers